What Is a Lithium Polymer Battery and Why Is It Replacing Traditional Lithium-Ion Batteries

A Lithium Polymer Battery has rapidly become one of the most preferred energy storage solutions across consumer electronics, medical devices, industrial equipment, and emerging smart technologies. Compared with conventional lithium-ion batteries, lithium polymer technology offers superior flexibility, enhanced safety potential, lightweight design, and greater customization options.

In this in-depth guide, we explore what a Lithium Polymer Battery is, how it works, why it is increasingly replacing traditional lithium-ion batteries, and how businesses can select the right solution for long-term performance and reliability.

Table of Contents

- Understanding What a Lithium Polymer Battery Is

- How a Lithium Polymer Battery Works

- Lithium Polymer Battery vs Traditional Lithium-Ion Battery

- Key Advantages Driving Lithium Polymer Battery Adoption

- Common Applications of a Lithium Polymer Battery

- Design Flexibility and Customization Options

- Safety Considerations and Best Practices

- How to Choose the Right Lithium Polymer Battery Supplier

- Frequently Asked Questions (FAQ)

1. Understanding What a Lithium Polymer Battery Is

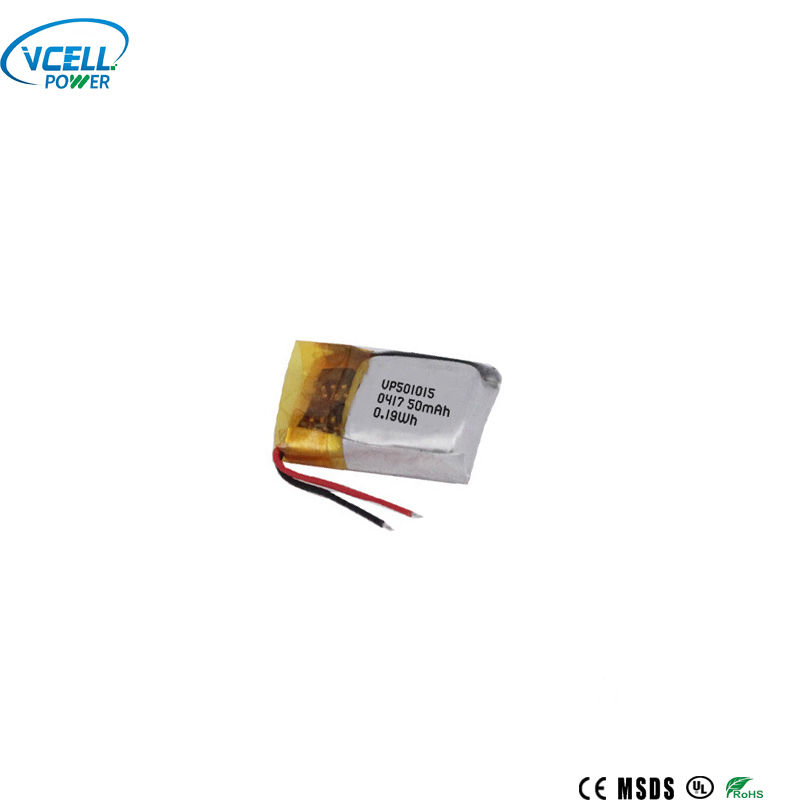

A Lithium Polymer Battery, often abbreviated as LiPo, is a rechargeable battery that uses a polymer-based electrolyte instead of the traditional liquid electrolyte found in standard lithium-ion cells. This polymer electrolyte can exist in gel or solid form, allowing the battery to be manufactured in ultra-thin, lightweight, and flexible shapes.

Unlike cylindrical or rigid prismatic lithium-ion batteries, a Lithium Polymer Battery is typically packaged in a soft aluminum-plastic pouch. This construction opens the door to innovative product designs where space, weight, and form factor are critical.

To learn more about industrial-grade solutions, you can explore detailed specifications on Lithium Polymer Battery solutions offered by VCELL POWER.

2. How a Lithium Polymer Battery Works

The fundamental working principle of a Lithium Polymer Battery is similar to that of a lithium-ion battery. Lithium ions move between the cathode and anode during charging and discharging cycles. The key difference lies in the electrolyte.

- Anode: Typically made from graphite, storing lithium ions during charging.

- Cathode: Commonly composed of lithium cobalt oxide, lithium iron phosphate, or other lithium compounds.

- Polymer Electrolyte: Acts as the medium that allows lithium ions to move safely between electrodes.

Because the polymer electrolyte is not free-flowing like liquid electrolytes, it significantly reduces the risk of leakage and enables thinner battery designs.

3. Lithium Polymer Battery vs Traditional Lithium-Ion Battery

| Feature | Lithium Polymer Battery | Traditional Lithium-Ion Battery |

|---|---|---|

| Electrolyte Type | Polymer or gel-based | Liquid electrolyte |

| Form Factor | Flexible, ultra-thin, custom shapes | Rigid cylindrical or prismatic |

| Weight | Lighter | Heavier |

| Design Freedom | High | Limited |

| Safety Potential | Higher with proper design | Moderate |

This comparison highlights why many manufacturers are shifting from traditional lithium-ion batteries to Lithium Polymer Battery solutions, especially for compact and high-performance devices.

4. Key Advantages Driving Lithium Polymer Battery Adoption

- Lightweight Construction: Ideal for portable and wearable electronics.

- Customizable Shapes: Enables innovative industrial and consumer product designs.

- High Energy Density: Delivers long runtime without increasing size.

- Low Self-Discharge: Maintains stored energy over extended periods.

- Improved Safety Engineering: Reduced leakage risk with polymer electrolytes.

These advantages make the Lithium Polymer Battery particularly attractive for OEMs seeking performance without compromising design flexibility.

5. Common Applications of a Lithium Polymer Battery

A Lithium Polymer Battery is widely used across various industries:

- Smartphones and tablets

- Wearable devices and smartwatches

- Medical monitoring equipment

- Bluetooth devices and IoT sensors

- Drones and RC devices

- Portable industrial instruments

At VCELL POWER, customized Lithium Polymer Battery packs are engineered to meet specific voltage, capacity, and safety requirements for each application scenario.

6. Design Flexibility and Customization Options

One of the most compelling reasons manufacturers choose a Lithium Polymer Battery is the ability to customize nearly every aspect of the battery design.

- Custom thickness and dimensions

- Tailored capacity and discharge rates

- Integrated protection circuits (PCM/BMS)

- Connector and wire customization

- Brand labeling and packaging

This level of customization ensures seamless integration into complex electronic systems while maintaining optimal performance.

7. Safety Considerations and Best Practices

While a Lithium Polymer Battery offers strong safety potential, proper design and usage remain essential.

- Use certified protection circuits to prevent overcharge and over-discharge

- Maintain operating temperatures within recommended limits

- Ensure quality manufacturing and cell matching

- Follow proper storage and transportation guidelines

Partnering with an experienced manufacturer like VCELL POWER helps ensure compliance with international safety standards and long-term reliability.

8. How to Choose the Right Lithium Polymer Battery Supplier

Selecting the right Lithium Polymer Battery supplier is as critical as choosing the battery itself.

- Proven industry experience and certifications

- Customization and engineering support

- Strict quality control processes

- Transparent technical documentation

- Reliable after-sales support

VCELL POWER combines technical expertise with flexible manufacturing capabilities, making it a trusted partner for global battery solutions.

9. Frequently Asked Questions (FAQ)

Is a Lithium Polymer Battery safer than lithium-ion?

When properly designed and protected, a Lithium Polymer Battery can offer improved safety due to reduced leakage risk and flexible packaging.

How long does a Lithium Polymer Battery last?

Typical lifespan ranges from 300 to 800 charge cycles, depending on usage conditions, charging habits, and operating environment.

Can a Lithium Polymer Battery be customized?

Yes. One of its biggest advantages is extensive customization in size, capacity, shape, and electrical configuration.

Are Lithium Polymer Batteries environmentally friendly?

They are more energy-efficient and lighter, which can reduce overall material usage, but proper recycling is still essential.

Conclusion

The rise of the Lithium Polymer Battery reflects the evolving demands of modern electronics for lighter, safer, and more adaptable power solutions. Its ability to replace traditional lithium-ion batteries lies in its superior design flexibility, performance potential, and application versatility.

If you are looking for a reliable, customizable, and high-quality Lithium Polymer Battery solution, VCELL POWER is ready to support your project from concept to mass production. To explore tailored battery solutions and discuss your specific requirements, contact us today and discover how advanced power technology can elevate your products.

Send Inquiry

-

WhatsApp

-

E-mail