Why Are Ni-MH Batteries Experiencing Strong Market Growth in Asia-Pacific?

2025-11-19

Over the past decade, the Asia‑Pacific region has witnessed a remarkable surge in demand for Ni‑MH Battery solutions. As a seasoned industry provider, VCELL POWER CO., LTD. has been closely observing and actively participating in this trend. In this article, we will analyze the key drivers behind this growth, highlight the technical advantages of Ni‑MH technology, and present our product parameter sheet to illustrate why our offerings are well aligned with market needs.

Market Dynamics Fueling Growth in Asia‑Pacific

The Asia‑Pacific market, encompassing countries such as China, Japan, South Korea, India, and Southeast Asian nations, is seeing a strong shift toward clean energy and hybrid mobility. Government incentives, stricter emissions regulations, and consumer demand for greener options are spurring investment in hybrid electric vehicles (HEVs) and renewable energy storage. In this context, Ni‑MH Battery technology offers a compelling value proposition due to its safety, reliability, and relatively low cost compared to other chemistries. VCELL POWER CO., LTD. has capitalized on this momentum by scaling up our production capacity in Asia. Our factory now produces high‑quality Ni‑MH Battery packs tailored to regional demand, helping accelerate the adoption of sustainable energy solutions.

Technical Advantages of Ni‑MH Chemistry

Ni‑MH Battery chemistry provides a number of advantages that make it particularly attractive for Asia‑Pacific applications:

- Robust Safety Profile: Ni‑MH cells are intrinsically safer than many high‑energy chemistries. They are less prone to thermal runaway and degradation under abuse conditions.

- Long Cycle Life: With proper design, Ni‑MH Battery systems can deliver upwards of thousands of cycles, making them ideal for frequent charge‑discharge applications like hybrid vehicles.

- Wide Temperature Tolerance: Many Asia‑Pacific markets experience wide thermal ranges; Ni‑MH performs well over a broad temperature window.

- Cost Efficiency: Nickel and metal hydride raw materials are often more affordable than rare‑earth or cobalt‑based alternatives, reducing manufacturing cost per kilowatt‑hour.

- Recyclability: Ni‑MH Battery cells are highly recyclable, aligning with circular economy goals and regulatory frameworks in Asia‑Pacific countries.

Key Applications Driving Demand

There are several major application areas in the Asia‑Pacific region that are fueling demand for Ni‑MH Battery technology:

- Hybrid Electric Vehicles (HEVs): Many automakers in Asia continue to favor Ni‑MH Battery packs for hybrid models, especially in markets where cost sensitivity is critical.

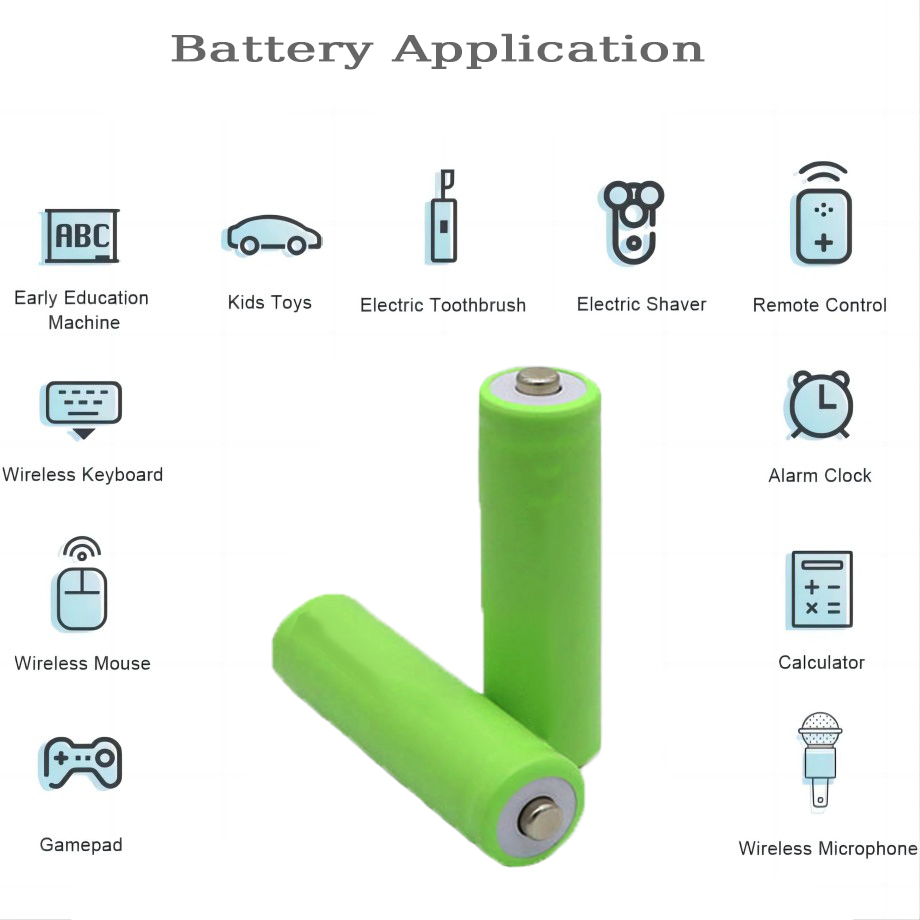

- Consumer Electronics: Rechargeable AA, AAA, and specialty battery segments in camera gear, portable audio, and industrial tools are strong consumers.

- Renewable Energy Storage: Ni‑MH-based stationary storage systems are gaining traction in off-grid and micro‑grid applications due to their safety and robustness.

- Industrial Backup Power: Applications such as telecommunications, UPS, and critical infrastructure benefit from the long life and safe chemistry of Ni‑MH Battery modules.

Our Product Parameter Sheet

To give you a clear understanding of our technical capabilities, below is a detailed parameter table for one of our flagship Ni‑MH Battery cell models:

| Specification | Parameter |

| Nominal Voltage | 1.2 V |

| Typical Capacity | 2,500 mAh |

| Maximum Discharge Current | 5 A (standard), 10 A (peak) |

| Cycle Life | ≥ 1,000 cycles @ 80% DOD |

| Self‑Discharge Rate | ≈ 10% per month at 20 °C |

| Operating Temperature Range | -20 °C to +60 °C |

| Charge Method | C‑rate: 0.1 C to 1 C, Delta‑V detection |

| Storage Recommendation | Store at 40%–50% charge in dry, cool environment |

| Weight | ≈ 28 g per cell |

This technical sheet demonstrates the maturity and robustness of our Ni‑MH Battery design. At VCELL POWER CO., LTD., we emphasize precision manufacturing and rigorous testing to ensure each cell meets international standards.

Manufacturing Capability and Quality Assurance

At VCELL POWER CO., LTD., our factory is outfitted with state‑of‑the‑art production lines. We employ automated assembly, strict process control, and advanced quality assurance systems. Our R&D engineers continuously improve the performance of our Ni‑MH Battery cells, optimizing materials, electrode formulation, and safety features. Through our continuous improvement protocols, our products deliver consistent performance, high cycle life, and long-term reliability.

Moreover, our supply chain strategy prioritizes regional sourcing of raw materials, reducing lead times and improving responsiveness to market shifts in Asia‑Pacific. We maintain tight control over production yields, and our rigorous testing regimen covers thermal abuse, vibration, and capacity retention.

Future Outlook in Asia‑Pacific

Going forward, the Asia‑Pacific region is expected to maintain its strong demand growth for Ni‑MH Battery technology. As hybrid vehicles remain a core part of the mobility mix, and off‑grid energy systems proliferate, we anticipate continued adoption. At VCELL POWER CO., LTD., our roadmap includes scaling up capacity, improving energy density, and expanding into new markets such as marine applications and stationary ESS.

Our commitment is to deliver cost‑effective, safe, and high‑performance Ni‑MH Battery solutions. We firmly believe that our expertise, combined with regional demand and favorable policies, positions us well to lead in this rapidly expanding market.

FAQ – Common Questions About Growth Trends

Q: Why are Ni‑MH batteries experiencing strong market growth in Asia‑Pacific?

A: The Asia‑Pacific region is seeing rapid adoption of hybrid electric vehicles, strong renewable energy deployment, and favorable government policies. These trends drive demand for Ni‑MH Battery technology, which offers safety, recyclability, and cost efficiency compared to other chemistries.

Q: Why do manufacturers still choose Ni‑MH over lithium‑ion in some Asia‑Pacific markets?

A: Manufacturers often favor Ni‑MH Battery in cost-sensitive applications like hybrids and backup systems, because it has a mature supply chain, reliable cycle life, and lower safety risks, making it a pragmatic choice for regional production and long-term usage.

Q: Why is the growth of Ni‑MH batteries particularly strong now?

A: Growth is accelerating due to tightening environmental regulations, consumer preference for greener products, regional incentives for clean energy, and improvements in Ni‑MH Battery performance from companies that invest in advanced manufacturing and R&D.

Conclusion

In summary, Ni‑MH Battery technology is enjoying a resurgence in the Asia‑Pacific region, driven by a combination of environmental policy, cost-effective hybrid adoption, and technical maturity. At VCELL POWER CO., LTD., our strategic commitment to this chemistry, backed by our advanced factory operations and deep regional expertise, positions us to meet the growing demand. We remain focused on developing high-quality Ni‑MH Battery solutions that deliver safety, performance, and value to customers across Asia‑Pacific.